Call us!

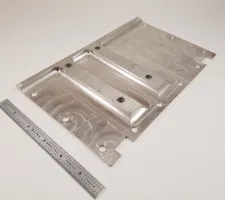

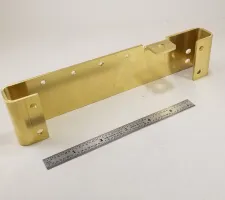

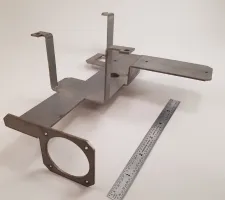

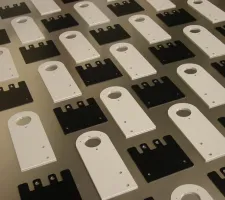

PLATE FABRICATION SERVICES

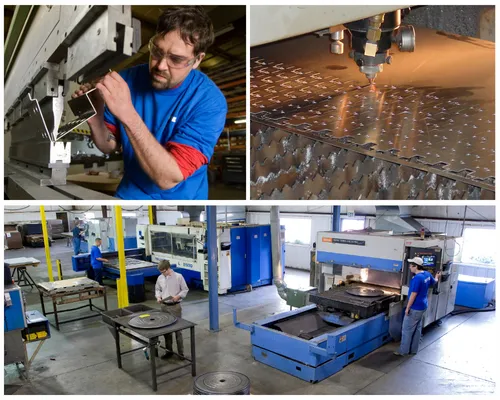

Specializing in laser cutting and machining of metal plates, brackets and custom components, we partner with OEMs, Contractors, and Fabricators to provide a consistent, repeatable, worry-free supply chain.

As a Certified ISO 9001 fabricator, our state-of-the-art facility in Fort Wayne, Indiana enables us to efficiently fabricate a broad range of products at both small and large volumes.

With low setup fees, high production capacity and a fast turnarounds, we make it easy to work with us!

Fill out the form and we'll be in touch in 2 hours or less!

METAL FABRICATION

Elevated Steel is your go-to company for metal fabrication. We are a custom fabricator and designer that offers a comprehensive range of services.

Design assistance

Fabrication (steel, aluminum, stainless, and more)

Welding

Finishing (powder coating, galvanization, wet coating)

Assembly

nstallation anywhere in the U.S.

We use only the best materials available to create strong, long-lasting products and work closely with our clients to provide specialized solutions that meet their demands. Keeping up with the latest technology and best practices are just some of the ways we’re striving to be your resource for all aspects of metal fabrication.

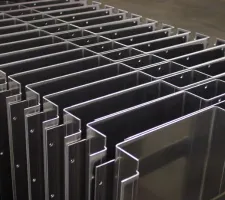

FABRICATION CAPABILITIES

With our fully-equipped fabrication shop in Indiana and a team of highly skilled machinists and welders, there's almost no job that we can't handle. Whether you need a 50 brackets or 5,000 custom machined plates, we have the capacity and the expertise to get you a quality product at a competitive price delivered on time.

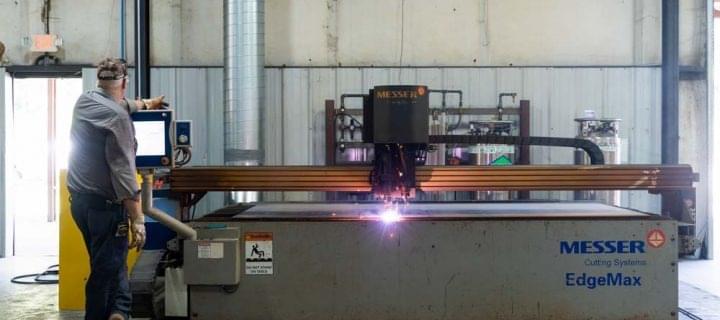

CUTTING & FORMING

CNC Laser Cutting up to 72" x 144" (see below for material thickness)

5 axis CNC Press Brake Forming up to 120” and 110 Tons

Production & Precision Sawing: 10” Round, 12” x 7” Rectangular

45 Ton OBI Punch Press

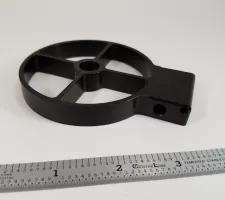

MACHINING

CNC Machining: 40 x 26 x 25”, with integrated CNC 4th Axis

Profile Milling +/- .001”, Holes +/- .0005”

Materials of all types including Steel, Stainless, Tool Steel, Aluminum, Brass, Plastics

Castings, Forgings, Bar, Pipe, Plate, and Billet

PRECISION TURNING

CNC Turning: 15” x 30”, Live Tooling, Sub-Spindle (x, z, c, b, v, a)

3” Diameter Through Spindle

Engine Lathe (up to 12” x 36”)

Profile Turning +/- .001”

Turned Diameters +/- .0005”

Castings, Forgings, Bar, Pipe, and Billet

VALUE-ADDED SERVICES

In additional to our laser cutting and machining services, we also offer upstream and downstream services that allow us to be a turnkey solution for our customers! From design and coating to product assembly and order fulfillment, we've got you covered with end-to-end solutions!

WELDING

TIG Welding (AWS Certified)

MIG Welding (AWS Certified)

Stud & Nut Welding

Spot Welding (Up to 75 KVA)

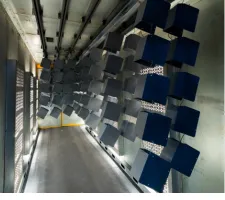

COATING

Powder Coating

Liquid Painting

Plating & Conversion Coatings

Heat Treatment

ASSEMBLY

Sub-Assembly

Packaging

Stocking

Order Fulfillment

DESIGN

Sub-Assembly

Packaging

Stocking

Order Fulfillment

About Us

ELEVATED STEEL

We are a TURNKEY solution! For decades, we’ve built our business on consistently going above and above for our customers. We pride ourselves on the fabrication that is both high-quality and on time.

We strive to stand out from the rest of the fabrication and installation companies. We want to collaborate with our clients in every project we take on and to work with partners who are reliable and trustworthy.

OUR CUSTOMERS

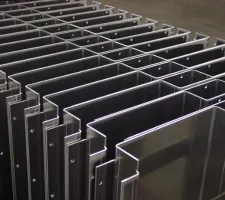

PROJECT GALLERY

WHY CUSTOMERS CHOOSE US

Combining 82 years of laser cutting, machining and welding experience, Precision Laser Services has the experience, equipment and skilled staff to exceed expectations on every order!

ADVANCED

CAPABILITIES

Our modern equipment and ISO-compliant processes enable us to deliver our customers' orders with shorter lead times and higher quality. Our Staff are dedicated to making our customers successful, one order at a time!

SUPERIOR

QUALITY

Quality is built in, such that getting it right the first time is the expectation. From our initial meeting to quoting to order delivery, our advanced product quality planning process is engineered to provide our customers with a reliable supply chain.

RELIABLE

DELIVERY

Driven by a deep sense of personal pride, each member of our staff is committed to ensuring absolute customer satisfaction. We refuse to accept mediocrity and we do everything in our power to deliver what we promised to our customers.

INDUSTRIES SERVED

MILITARY

FOOD GRADE

TRANSPORTATION

MARINE

MEDICAL

RV

MANUFACTURING

AND MORE!

PLS QUALITY PROCESS

Advanced Product Quality Planning (APQP) is at the heart of our commitment to reliability. This structured approach ensures every project goes through a meticulous process, from initial meetings to discuss your requirements, through quoting, approval, and execution. Our APQP methodology focuses on thorough cross-functional analysis, advanced planning, and the development of practical tools and materials, ensuring your project meets quality, timing, and budget expectations. With this process, we provide a reliable supply chain, ensuring stability and repeatability for your parts.

Let’s talk about your project

OTHER COMMON APPLICATIONS

MECHANICAL PARTS & ASSEMBLIES

FITTINGS

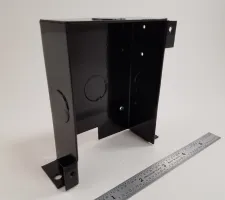

PANELS & ENCLOSURES

CUSTOM SHEET

METAL

MEDICAL EQUIPMENT

BASE PLATES & EMBED PLATES

BRACKETS & MOUNTS

CUSTOM FRAMES

FREQUENTLY ASKED QUESTIONS

What sheet size can you cut?

Our laser cutter can handle sheets up to 72" x 144"

What is your accuracy?

Laser Cutting +/- .005”

Profile Milling +/- .001”, Holes +/- .0005”

Profile Turning +/- .001”Turned Diameters +/- .0005”

How thick can you cut?

Our laser has the following capacities:

Steel up to 3/4"

Stainless Steel up to 1/2"

Aluminum up to 1/2"

Brass & Copper up to 1/4"

ABOUT PRECISION LASER SERVICES

YOUR PARTNER FOR LASER CUTTING, FORMING & MACHINING

From our beginnings in 1942, responding to our customers needs with innovation has been a key part of delivering value to our customers. We focus on producing parts to your design, using the most cost effective methods available, and delivering these parts when and how you want them; thus, making your fabrication supply chain worry free.

With our modern, 30,000 square foot ISO 9001-certified manufacturing facility located in northeast Indiana, we are a full-service laser cutting, metal forming and machining partner, dedicated to providing quality, cost-effective fabrication solutions.

Our specialized capabilities and customer-centric culture enable us to adapt to our clients' evolving needs, ensuring the success of every project. Our team of skilled professionals are committed to delivering on our promises.

When you choose Precision Laser Services, you're not just choosing a supplier; you're choosing a partner dedicated to your success.

Let’s talk about your project

Connect With Our Team!

Fill out the form and we'll be in touch within 2 hours!

Want to reach out directly?

There's almost no job we can't handle,

so let us know how we can help!

Production Plant Location:

14730 Lima Rd

Fort Wayne, IN 46818

Office Hours:

Monday - Friday

8:00 am to 5:00 pm

Phone:

260-818-5161

Let’s talk about your project

Precision Laser Services

We're your local ISO-certified partner for laser cutting, metal forming and machining!

Reach out for an accurate quote and reliable delivery!

EQUIPMENT WE USE

Voortman V807

Plasma Cutter

EMI EL2

20’ brake

20’ shear

WE FOCUS ON QUALITY

AISC Compliant

Every part is quality checked

Certified Welders – 1,2,3,4G certifications (MIG and stick welding), GMAW and SMAW

AWS D1.1 compliant

LET'S TALK ABOUT YOUR PROJECT

For decades, we’ve built our business on consistently going above and above for our customers. We pride ourselves on fabrication that is both high quality and on time. We collaborate with our clients on every project we take on and to work with partners who are reliable and trustworthy.

Reach out to us by calling us or filling out this form and we will be in touch to talk about your project as soon as we can.

CONTACT INFORMATION